Unleashing the Power of a UV DTF Printer: Tips and Tricks for Optimal Results

UV DTF printing technology is a revolutionary method of printing that has gained popularity in recent years. This technology allows for high-quality, vibrant prints on a variety of substrates, making it a versatile option for many industries. Understanding the basics of UV DTF printing technology is crucial for anyone looking to utilize this technology to its full potential.

Understanding the Basics of UV DTF Printing Technology

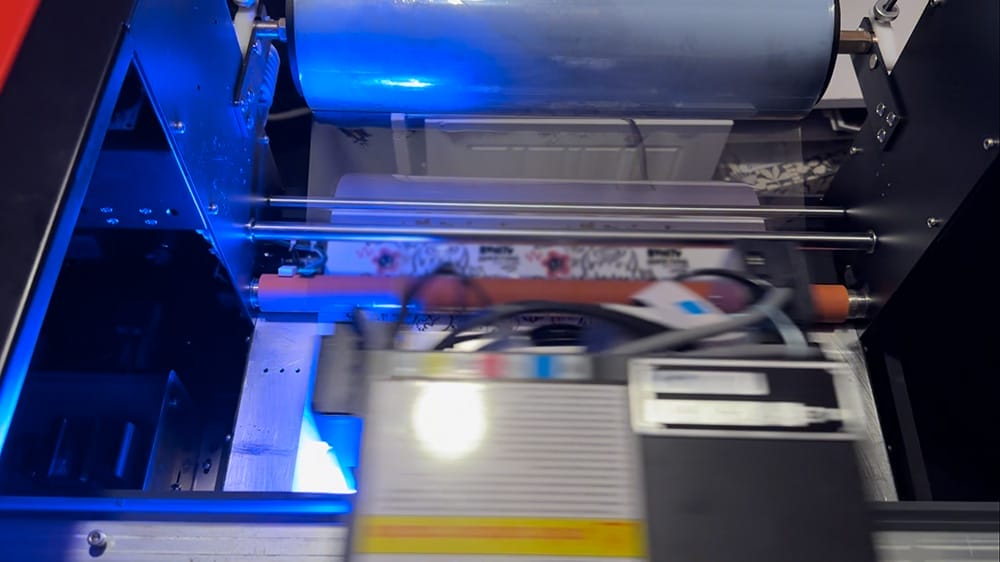

UV DTF printing technology, also known as UV Direct to Film printing, is a process that involves printing directly onto a film substrate using UV-curable inks. This technology offers several advantages over traditional printing methods, including faster production times, higher print quality, and the ability to print on a wide range of materials.

One of the key advantages of UV DTF printing technology is its ability to print on non-porous substrates, such as glass, metal, and plastic. This opens up a world of possibilities for industries such as signage, packaging, and promotional products. Additionally, UV DTF printing technology offers excellent color vibrancy and durability, making it ideal for outdoor applications.

Compared to other printing technologies, such as screen printing and offset printing, UV DTF printing offers faster production times and lower setup costs. This is because UV DTF printing does not require the use of plates or screens, resulting in a more streamlined and efficient printing process.

Choosing the Right Substrates for UV DTF Printing

Choosing the right substrate is crucial for achieving optimal results with UV DTF printing. The substrate plays a significant role in the final appearance and durability of the print. It is important to select a substrate that is compatible with UV-curable inks and can withstand the curing process.

There are several types of substrates that are suitable for UV DTF printing, including rigid materials like acrylic, PVC, and aluminum, as well as flexible materials like vinyl and fabric. When choosing a substrate, it is important to consider factors such as the intended use of the printed product, the desired finish, and the durability requirements.

In addition to the type of substrate, other factors to consider when choosing substrates for UV DTF printing include the surface texture, color, and thickness. Smooth, non-porous surfaces tend to produce the best results, as they allow for better ink adhesion and color vibrancy. It is also important to ensure that the substrate is properly prepared and free of any contaminants that could affect the print quality.

Preparing Artwork for UV DTF Printing: Best Practices

Proper artwork preparation is essential for achieving high-quality prints with UV DTF printing. This involves ensuring that the artwork is in the correct file format, has the appropriate resolution, and is properly color-managed.

When preparing artwork for UV DTF printing, it is important to use vector-based graphics whenever possible. Vector graphics are resolution-independent, meaning they can be scaled up or down without losing any quality. This is especially important for large-format prints, as it allows for crisp, clear images.

The resolution of the artwork is also important. For UV DTF printing, a resolution of 300 dots per inch (dpi) is typically recommended for optimal print quality. This ensures that the details of the artwork are captured accurately and that the final print appears sharp and clear.

Color management is another crucial aspect of artwork preparation for UV DTF printing. It is important to ensure that the colors in the artwork are accurately represented on the final print. This can be achieved through the use of color profiles and calibration techniques.

Tips for Achieving Optimal Ink Adhesion with UV DTF Printing

Achieving optimal ink adhesion is crucial for ensuring that the print is durable and long-lasting. Poor ink adhesion can result in the print peeling or fading over time. There are several factors that can affect ink adhesion with UV DTF printing, including the substrate, ink formulation, and curing process.

One of the key factors that affect ink adhesion is the surface preparation of the substrate. It is important to ensure that the substrate is properly cleaned and free of any contaminants that could interfere with the adhesion of the ink. This can be done using a variety of cleaning methods, such as wiping the surface with a lint-free cloth and a mild detergent.

The ink formulation also plays a role in ink adhesion. UV-curable inks are designed to adhere to a wide range of substrates, but different formulations may have different adhesion properties. It is important to choose an ink formulation that is compatible with the substrate and to follow the manufacturer’s recommendations for curing times and temperatures.

The curing process is another important factor to consider for achieving optimal ink adhesion. UV DTF printing uses UV light to cure the ink, which causes it to harden and adhere to the substrate. It is important to ensure that the ink is properly cured to achieve maximum adhesion. This can be done by using the correct curing settings on the printer and ensuring that the substrate is exposed to the UV light for the recommended amount of time.

Maximizing Color Accuracy with UV DTF Printing: Calibration and Color Management

Color accuracy is crucial for achieving high-quality prints with UV DTF printing. Proper calibration and color management techniques can help ensure that the colors in the artwork are accurately represented on the final print.

Calibration is the process of adjusting the color settings on the printer to ensure that the colors are reproduced accurately. This involves adjusting the color temperature, brightness, and contrast settings to match the desired color output. Calibration should be done regularly to account for any changes in the printer or environment.

Color management involves the use of color profiles to ensure that the colors in the artwork are accurately represented on the final print. Color profiles are files that contain information about how colors should be displayed or printed. They help ensure that the colors in the artwork are translated correctly to the printer’s color space.

There are several tools and software available for color management in UV DTF printing. These include spectrophotometers, which measure the color of a printed sample and create a color profile based on the measured values. There are also software programs that can help with color management, such as Adobe Photoshop and RIP software.

Troubleshooting Common Issues with UV DTF Printing

Like any printing technology, UV DTF printing can sometimes encounter issues that affect the quality of the prints. It is important to be familiar with common issues and troubleshooting techniques to ensure that any problems are resolved quickly and effectively.

One common issue with UV DTF printing is banding, which is the appearance of horizontal lines or streaks in the print. This can be caused by a variety of factors, including printhead misalignment, clogged nozzles, or incorrect print settings. Troubleshooting techniques for banding include cleaning the printhead, adjusting the print settings, or recalibrating the printer.

Another common issue is color inconsistency, where the colors in the artwork do not match the colors on the final print. This can be caused by factors such as incorrect color profiles, improper color management settings, or variations in the curing process. Troubleshooting techniques for color inconsistency include recalibrating the printer, adjusting the color management settings, or using a different ink formulation.

Preventative measures can also be taken to avoid common issues with UV DTF printing. This includes regular maintenance and cleaning of the printer, using high-quality substrates and inks, and following the manufacturer’s recommendations for print settings and curing times.

Maintaining Your UV DTF Printer: Cleaning and Maintenance Tips

Proper maintenance and cleaning of your UV DTF printer is essential for ensuring optimal performance and print quality. Regular maintenance can help prevent issues such as clogged nozzles, banding, and color inconsistency.

Cleaning the printhead is one of the most important maintenance tasks for UV DTF printers. This involves removing any ink residue or debris that may have accumulated on the printhead. There are several methods for cleaning the printhead, including using cleaning solutions, wiping with a lint-free cloth, or using a printhead cleaning kit.

In addition to cleaning the printhead, it is also important to clean other parts of the printer, such as the platen and the ink system. This can be done using a lint-free cloth and a mild detergent. It is important to follow the manufacturer’s recommendations for cleaning and maintenance to avoid damaging the printer.

Regular maintenance tasks for UV DTF printers include checking and replacing ink cartridges, inspecting and cleaning the media feed system, and calibrating the printer. It is important to follow a recommended maintenance schedule to ensure that the printer is functioning at its best.

Exploring Creative Applications for UV DTF Printing

UV DTF printing offers a wide range of creative applications, making it a popular choice for artists, designers, and businesses looking to create unique and innovative products. The ability to print on a variety of substrates opens up endless possibilities for customization and personalization.

One creative application for UV DTF printing is the production of custom signage and displays. UV DTF printing allows for vibrant, high-resolution prints on materials such as acrylic, PVC, and aluminum, making it ideal for creating eye-catching signs and displays. The ability to print directly onto rigid substrates also eliminates the need for additional mounting or framing.

Another creative application is the production of custom promotional products. UV DTF printing can be used to print logos, designs, and branding onto a variety of products, such as pens, keychains, and phone cases. This allows businesses to create unique and personalized promotional items that stand out from the competition.

UV DTF printing is also popular in the fashion and textile industry. It can be used to print designs onto fabrics, such as t-shirts, hoodies, and tote bags. The ability to print directly onto fabric allows for vibrant, durable prints that do not crack or fade over time.

Enhancing Your UV DTF Prints with Specialty Inks and Finishes

Specialty inks and finishes can be used to enhance the appearance and durability of UV DTF prints. These include metallic inks, textured finishes, and gloss or matte coatings.

Metallic inks can be used to add a touch of luxury and elegance to UV DTF prints. These inks contain metallic particles that create a shimmering effect when exposed to light. Metallic inks are often used in the production of high-end packaging, invitations, and promotional materials.

Textured finishes can be used to add depth and tactile interest to UV DTF prints. These finishes can mimic the look and feel of materials such as leather, wood, or fabric. Textured finishes are often used in the production of luxury packaging, book covers, and business cards.

Gloss or matte coatings can be used to protect UV DTF prints and enhance their appearance. Gloss coatings create a shiny, reflective surface, while matte coatings create a smooth, non-reflective surface. These coatings can help protect the print from scratches, fading, and moisture damage.

Best Practices for Marketing and Selling Your UV DTF Printed Products

Marketing and selling UV DTF printed products requires a strategic approach to stand out in a competitive market. It is important to understand your target audience, create a strong brand identity, and utilize effective marketing channels.

One of the key best practices for marketing UV DTF printed products is to understand your target audience. This involves conducting market research to identify the needs, preferences, and buying habits of your target customers. This information can then be used to tailor your marketing messages and product offerings to meet their needs.

Creating a strong brand identity is also important for marketing and selling UV DTF printed products. This involves developing a unique and memorable brand name, logo, and visual identity. Consistency in branding across all marketing channels helps to build brand recognition and trust with customers.

Utilizing effective marketing channels is crucial for reaching your target audience and generating sales. This can include online channels such as social media, email marketing, and e-commerce platforms, as well as offline channels such as trade shows, print advertising, and direct mail. It is important to choose the channels that are most effective for reaching your target audience and to track the results of your marketing efforts to make informed decisions.

Conclusion

UV DTF printing technology offers a wide range of benefits and applications, making it a versatile option for many industries. Understanding the basics of UV DTF printing technology, choosing the right substrates, preparing artwork, achieving optimal ink adhesion, and maximizing color accuracy are all crucial for achieving high-quality prints. Regular maintenance and cleaning of the printer, exploring creative applications, and utilizing specialty inks and finishes can enhance the appearance and durability of UV DTF prints. By following best practices for marketing and selling UV DTF printed products, businesses can stand out in a competitive market and maximize their success. With its potential for growth and innovation, UV DTF printing technology is set to revolutionize the printing industry.